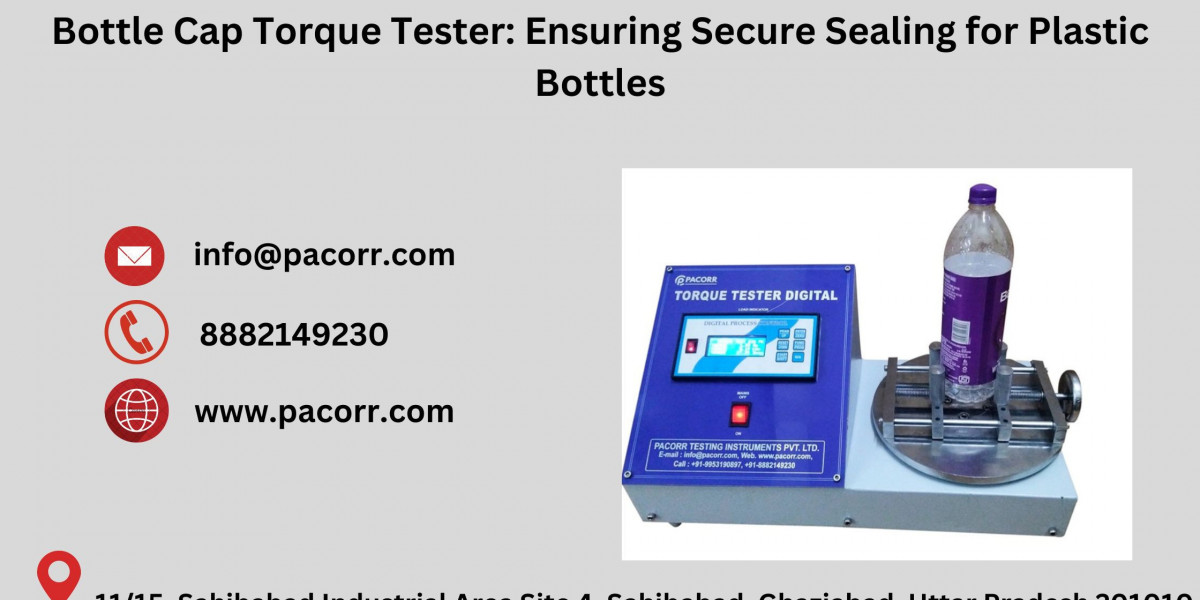

Bottle Cap Torque Tester: Ensuring Reliable Seal Integrity on pacorr.com

In industries like food and beverages, pharmaceuticals, cosmetics, and packaging, the quality of bottle cap seals is crucial for product integrity, safety, and customer satisfaction. The Bottle Cap Torque Tester is a specialized instrument designed to measure the torque required to open or close caps on bottles. This precision tool ensures that products remain securely sealed while still being easy to open for the end user. In this article, we will explore the importance, functionality, and benefits of the Bottle Cap Torque Tester and why it is essential for quality control in various industries.

Why Torque Testing is Vital for Bottle Caps

Bottle caps play an essential role in product preservation and safety. For instance, in the food and beverage industry, a tight seal ensures freshness, prevents contamination, and extends shelf life. However, caps that are too tight can frustrate customers, while loose caps may lead to spills or spoilage. Torque testing helps manufacturers ensure that the seal integrity is maintained without making the cap too difficult to open.

The Bottle Cap Torque Tester Price from pacorr.com provides precise measurements of the torque force, allowing quality control teams to set optimal torque limits and verify consistency during production.

Key Features of the Bottle Cap Torque Tester on pacorr.com

- High Accuracy and Reliability: Pacorr’s Bottle Cap Torque Tester is equipped with advanced sensors that offer high accuracy in measuring the torque force. This ensures manufacturers can rely on accurate data for quality control.

- User-Friendly Design: The instrument is designed for ease of use, with an intuitive interface that requires minimal training. Its compact size also makes it a practical choice for factory floors and laboratories.

- Versatile Testing Options: This tester can measure both the application (capping) and removal (decapping) torque, allowing manufacturers to ensure caps meet ideal force thresholds for both processes.

- Data Recording and Analysis: pacorr.com offers models with digital displays and data logging capabilities, enabling operators to record torque values and analyze trends over time.

- Adjustable Fixture Design: To accommodate different bottle sizes and cap styles, the tester features adjustable fixtures. This adaptability makes it ideal for industries where a variety of packaging types are used.

Applications and Benefits of Using the Bottle Cap Torque Tester

- Improved Quality Control: With precise torque measurements, companies can ensure that every bottle meets the desired torque specification, reducing the risk of product recalls and enhancing brand reliability.

- Enhanced Customer Experience: By maintaining the optimal torque, manufacturers can ensure that caps are neither too loose nor overly tight, thus improving customer convenience.

- Regulatory Compliance: In many industries, there are specific standards and regulations for packaging. The Bottle Cap Torque Tester from pacorr.com helps manufacturers meet these quality benchmarks, which can vary based on region and product type.

- Reduced Waste and Costs: Consistent torque testing helps in minimizing packaging defects, leading to cost savings and reduced waste from rejected products.

Conclusion

In today’s competitive market, the smallest details can make a significant difference in product quality and customer satisfaction. The Bottle Cap Torque Testing from pacorr.com ensures that manufacturers can provide customers with safe, high-quality products that meet industry standards. By using this tool for rigorous quality control, industries can reduce packaging defects, comply with regulations, and enhance the customer experience.